Resistors are common elements of electrical networks and electronic circuits and are ubiquitous in electronic equipment. Practical resistors as discrete components can be composed of various compounds and forms. Resistors are also implemented within integrated circuits.

The electrical function of a resistor is specified by its resistance: common commercial resistors are manufactured over a range of more than nine orders of magnitude. The nominal value of the resistance will fall within a manufacturing tolerance.

Electronic symbols and notation

-

IEC resistor symbol

Theory of operation

The hydraulic analogy

compares electric current flowing through circuits to water flowing

through pipes. When a pipe (left) is filled with hair (right), it takes a

larger pressure to achieve the same flow of water. Pushing electric

current through a large resistance is like pushing water through a pipe

clogged with hair: It requires a larger push (voltage drop) to drive the same flow (electric current).[1]

Ohm's law

Practical resistors also have some inductance and capacitance which will also affect the relation between voltage and current in alternating current circuits.

The ohm (symbol: Ω) is the SI unit of electrical resistance, named after Georg Simon Ohm. An ohm is equivalent to a volt per ampere. Since resistors are specified and manufactured over a very large range of values, the derived units of milliohm (1 mΩ = 10−3 Ω), kilohm (1 kΩ = 103 Ω), and megohm (1 MΩ = 106 Ω) are also in common usage.

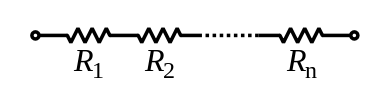

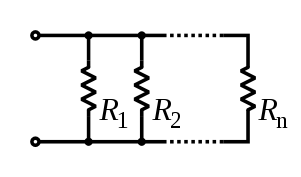

Series and parallel resistors

The total resistance of resistors connected in series is the sum of their individual resistance values.

The total resistance of resistors connected in parallel is the reciprocal of the sum of the reciprocals of the individual resistors.

So, for example, a 10 ohm resistor connected in parallel with a 5 ohm resistor and a 15 ohm resistor will produce the inverse of 1/10+1/5+1/15 ohms of resistance, or 1/(.1+.2+.067)=2.725 ohms.

A resistor network that is a combination of parallel and series connections can be broken up into smaller parts that are either one or the other. Some complex networks of resistors cannot be resolved in this manner, requiring more sophisticated circuit analysis. Generally, the Y-Δ transform, or matrix methods can be used to solve such problems.[2][3][4]

Power dissipation

At any instant of time, the power P (watts) consumed by a resistor of resistance R (ohms) is calculated as: where V (volts) is the voltage across the resistor and I (amps) is the current flowing through it. Using Ohm's law,

the two other forms can be derived. This power is converted into heat

which must be dissipated by the resistor's package before its

temperature rises excessively.

where V (volts) is the voltage across the resistor and I (amps) is the current flowing through it. Using Ohm's law,

the two other forms can be derived. This power is converted into heat

which must be dissipated by the resistor's package before its

temperature rises excessively.Resistors are rated according to their maximum power dissipation. Most discrete resistors in solid-state electronic systems absorb much less than a watt of electrical power and require no attention to their power rating. Such resistors in their discrete form, including most of the packages detailed below, are typically rated as 1/10, 1/8, or 1/4 watt.

An aluminium-housed power resistor rated for 50 W when heat-sinked

If the average power dissipated by a resistor is more than its power rating, damage to the resistor may occur, permanently altering its resistance; this is distinct from the reversible change in resistance due to its temperature coefficient when it warms. Excessive power dissipation may raise the temperature of the resistor to a point where it can burn the circuit board or adjacent components, or even cause a fire. There are flameproof resistors that fail (open circuit) before they overheat dangerously.

Since poor air circulation, high altitude, or high operating temperatures may occur, resistors may be specified with higher rated dissipation than will be experienced in service.

All resistors have a maximum voltage rating; this may limit the power dissipation for higher resistance values.

Nonideal properties

Practical resistors have a series inductance and a small parallel capacitance; these specifications can be important in high-frequency applications. In a low-noise amplifier or pre-amp, the noise characteristics of a resistor may be an issue.The temperature coefficient of the resistance may also be of concern in some precision applications.

The unwanted inductance, excess noise, and temperature coefficient are mainly dependent on the technology used in manufacturing the resistor. They are not normally specified individually for a particular family of resistors manufactured using a particular technology.[5] A family of discrete resistors is also characterized according to its form factor, that is, the size of the device and the position of its leads (or terminals) which is relevant in the practical manufacturing of circuits using them.

Practical resistors are also specified as having a maximum power rating which must exceed the anticipated power dissipation of that resistor in a particular circuit: this is mainly of concern in power electronics applications. Resistors with higher power ratings are physically larger and may require heat sinks. In a high-voltage circuit, attention must sometimes be paid to the rated maximum working voltage of the resistor. While there is no minimum working voltage for a given resistor, failure to account for a resistor's maximum rating may cause the resistor to incinerate when current is run through it.

Fixed resistor

A single in line (SIL) resistor package with 8 individual, 47 ohm

resistors. One end of each resistor is connected to a separate pin and

the other ends are all connected together to the remaining (common) pin –

pin 1, at the end identified by the white dot.

Lead arrangements

Resistors with wire leads for through-hole mounting

Carbon composition

Three carbon composition resistors in a 1960s valve (vacuum tube) radio

The resistive element is made from a mixture of finely ground (powdered) carbon and an insulating material (usually ceramic). A resin holds the mixture together. The resistance is determined by the ratio of the fill material (the powdered ceramic) to the carbon. Higher concentrations of carbon— a good conductor— result in lower resistance. Carbon composition resistors were commonly used in the 1960s and earlier, but are not so popular for general use now as other types have better specifications, such as tolerance, voltage dependence, and stress (carbon composition resistors will change value when stressed with over-voltages). Moreover, if internal moisture content (from exposure for some length of time to a humid environment) is significant, soldering heat will create a non-reversible change in resistance value. Carbon composition resistors have poor stability with time and were consequently factory sorted to, at best, only 5% tolerance.[6] These resistors, however, if never subjected to overvoltage nor overheating were remarkably reliable considering the component's size.[7]

Carbon composition resistors are still available, but comparatively quite costly. Values ranged from fractions of an ohm to 22 megohms. Due to their high price, these resistors are no longer used in most applications. However, they are used in power supplies and welding controls.[7]

Carbon pile

A carbon pile resistor is made of a stack of carbon disks compressed between two metal contact plates. Adjusting the clamping pressure changes the resistance between the plates. These resistors are used when an adjustable load is required, for example in testing automotive batteries or radio transmitters. A carbon pile resistor can also be used as a speed control for small motors in household appliances (sewing machines, hand-held mixers) with ratings up to a few hundred watts.[8] A carbon pile resistor can be incorporated in automatic voltage regulators for generators, where the carbon pile controls the field current to maintain relatively constant voltage.[9] The principle is also applied in the carbon microphone.Carbon film

Carbon film resistor with exposed carbon spiral (Tesla TR-212 1 kΩ)

Printed carbon resistor

A carbon resistor printed directly onto the SMD pads on a PCB. Inside a 1989 vintage Psion II Organiser

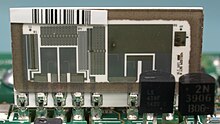

Thick and thin film

Laser Trimmed Precision Thin Film Resistor Network from Fluke, used in

the Keithley DMM7510 multimeter. Ceramic backed with glass hermetic seal

cover.

Thin film resistors are made by sputtering (a method of vacuum deposition) the resistive material onto an insulating substrate. The film is then etched in a similar manner to the old (subtractive) process for making printed circuit boards; that is, the surface is coated with a photo-sensitive material, then covered by a pattern film, irradiated with ultraviolet light, and then the exposed photo-sensitive coating is developed, and underlying thin film is etched away.

Thick film resistors are manufactured using screen and stencil printing processes.[7]

Because the time during which the sputtering is performed can be controlled, the thickness of the thin film can be accurately controlled. The type of material is also usually different consisting of one or more ceramic (cermet) conductors such as tantalum nitride (TaN), ruthenium oxide (RuO

2), lead oxide (PbO), bismuth ruthenate (Bi

2Ru

2O

7), nickel chromium (NiCr), or bismuth iridate (Bi

2Ir

2O

7).

The resistance of both thin and thick film resistors after manufacture is not highly accurate; they are usually trimmed to an accurate value by abrasive or laser trimming. Thin film resistors are usually specified with tolerances of 0.1, 0.2, 0.5, or 1%, and with temperature coefficients of 5 to 25 ppm/K. They also have much lower noise levels, on the level of 10–100 times less than thick film resistors.[citation needed]

Thick film resistors may use the same conductive ceramics, but they are mixed with sintered (powdered) glass and a carrier liquid so that the composite can be screen-printed. This composite of glass and conductive ceramic (cermet) material is then fused (baked) in an oven at about 850 °C.

Thick film resistors, when first manufactured, had tolerances of 5%, but standard tolerances have improved to 2% or 1% in the last few decades. Temperature coefficients of thick film resistors are high, typically ±200 or ±250 ppm/K; a 40 kelvin (70 °F) temperature change can change the resistance by 1%.

Thin film resistors are usually far more expensive than thick film resistors. For example, SMD thin film resistors, with 0.5% tolerances, and with 25 ppm/K temperature coefficients, when bought in full size reel quantities, are about twice the cost of 1%, 250 ppm/K thick film resistors.

Metal film

A common type of axial-leaded resistor today is the metal-film resistor. Metal Electrode Leadless Face (MELF) resistors often use the same technology, and are also cylindrically shaped but are designed for surface mounting. Note that other types of resistors (e.g., carbon composition) are also available in MELF packages.Metal film resistors are usually coated with nickel chromium (NiCr), but might be coated with any of the cermet materials listed above for thin film resistors. Unlike thin film resistors, the material may be applied using different techniques than sputtering (though this is one of the techniques). Also, unlike thin-film resistors, the resistance value is determined by cutting a helix through the coating rather than by etching. (This is similar to the way carbon resistors are made.) The result is a reasonable tolerance (0.5%, 1%, or 2%) and a temperature coefficient that is generally between 50 and 100 ppm/K.[12] Metal film resistors possess good noise characteristics and low non-linearity due to a low voltage coefficient. Also beneficial are their tight tolerance, low temperature coefficient and long-term stability.[7]

Metal oxide film

Metal-oxide film resistors are made of metal oxides such as tin oxide. This results in a higher operating temperature and greater stability/reliability than Metal film. They are used in applications with high endurance demands.Wire wound

High-power wire wound resistors used for dynamic braking on an electric railway car. Such resistors may dissipate many kilowatts for an extended length of time.

Types of windings in wire resistors:

1. common

2. bifilar

3. common on a thin former

4. Ayrton-Perry

1. common

2. bifilar

3. common on a thin former

4. Ayrton-Perry

Because wirewound resistors are coils they have more undesirable inductance than other types of resistor, although winding the wire in sections with alternately reversed direction can minimize inductance. Other techniques employ bifilar winding, or a flat thin former (to reduce cross-section area of the coil). For the most demanding circuits, resistors with Ayrton-Perry winding are used.

Applications of wirewound resistors are similar to those of composition resistors with the exception of the high frequency. The high frequency response of wirewound resistors is substantially worse than that of a composition resistor.[7]

Foil resistor

The primary resistance element of a foil resistor is a special alloy foil several micrometers thick. Since their introduction in the 1960s, foil resistors have had the best precision and stability of any resistor available. One of the important parameters influencing stability is the temperature coefficient of resistance (TCR). The TCR of foil resistors is extremely low, and has been further improved over the years. One range of ultra-precision foil resistors offers a TCR of 0.14 ppm/°C, tolerance ±0.005%, long-term stability (1 year) 25 ppm, (3 years) 50 ppm (further improved 5-fold by hermetic sealing), stability under load (2000 hours) 0.03%, thermal EMF 0.1 μV/°C, noise −42 dB, voltage coefficient 0.1 ppm/V, inductance 0.08 μH, capacitance 0.5 pF.[13]Ammeter shunts

An ammeter shunt is a special type of current-sensing resistor, having four terminals and a value in milliohms or even micro-ohms. Current-measuring instruments, by themselves, can usually accept only limited currents. To measure high currents, the current passes through the shunt across which the voltage drop is measured and interpreted as current. A typical shunt consists of two solid metal blocks, sometimes brass, mounted on an insulating base. Between the blocks, and soldered or brazed to them, are one or more strips of low temperature coefficient of resistance (TCR) manganin alloy. Large bolts threaded into the blocks make the current connections, while much smaller screws provide volt meter connections. Shunts are rated by full-scale current, and often have a voltage drop of 50 mV at rated current. Such meters are adapted to the shunt full current rating by using an appropriately marked dial face; no change need to be made to the other parts of the meter.Grid resistor

In heavy-duty industrial high-current applications, a grid resistor is a large convection-cooled lattice of stamped metal alloy strips connected in rows between two electrodes. Such industrial grade resistors can be as large as a refrigerator; some designs can handle over 500 amperes of current, with a range of resistances extending lower than 0.04 ohms. They are used in applications such as dynamic braking and load banking for locomotives and trams, neutral grounding for industrial AC distribution, control loads for cranes and heavy equipment, load testing of generators and harmonic filtering for electric substations.[14][15]The term grid resistor is sometimes used to describe a resistor of any type connected to the control grid of a vacuum tube. This is not a resistor technology; it is an electronic circuit topology.

Special varieties

Variable resistors

Adjustable resistors

A resistor may have one or more fixed tapping points so that the resistance can be changed by moving the connecting wires to different terminals. Some wirewound power resistors have a tapping point that can slide along the resistance element, allowing a larger or smaller part of the resistance to be used.Where continuous adjustment of the resistance value during operation of equipment is required, the sliding resistance tap can be connected to a knob accessible to an operator. Such a device is called a rheostat and has two terminals.

Potentiometers

Main article: Potentiometer

A potentiometer or pot

is a three-terminal resistor with a continuously adjustable tapping

point controlled by rotation of a shaft or knob or by a linear slider.

It is called a potentiometer because it can be connected as an

adjustable voltage divider to provide a variable potential at the terminal connected to the tapping point. A volume control for an audio device is a common use of a potentiometer.Accurate, high-resolution panel-mounted potentiometers have resistance elements typically wirewound on a helical mandrel, although some include a conductive-plastic resistance coating over the wire to improve resolution. These typically offer ten turns of their shafts to cover their full range. They are usually set with dials that include a simple turns counter and a graduated dial. Electronic analog computers used them in quantity for setting coefficients, and delayed-sweep oscilloscopes of recent decades included one on their panels.

Resistance decade boxes

Resistance decade box "KURBELWIDERSTAND", made in former East Germany.

Special devices

There are various devices whose resistance changes with various quantities. The resistance of NTC thermistors exhibit a strong negative temperature coefficient, making them useful for measuring temperatures. Since their resistance can be large until they are allowed to heat up due to the passage of current, they are also commonly used to prevent excessive current surges when equipment is powered on. Similarly, the resistance of a humistor varies with humidity. One sort of photodetector, the photoresistor, has a resistance which varies with illumination.The strain gauge, invented by Edward E. Simmons and Arthur C. Ruge in 1938, is a type of resistor that changes value with applied strain. A single resistor may be used, or a pair (half bridge), or four resistors connected in a Wheatstone bridge configuration. The strain resistor is bonded with adhesive to an object that will be subjected to mechanical strain. With the strain gauge and a filter, amplifier, and analog/digital converter, the strain on an object can be measured.

A related but more recent invention uses a Quantum Tunnelling Composite to sense mechanical stress. It passes a current whose magnitude can vary by a factor of 1012 in response to changes in applied pressure.

Measurement

The value of a resistor can be measured with an ohmmeter, which may be one function of a multimeter. Usually, probes on the ends of test leads connect to the resistor. A simple ohmmeter may apply a voltage from a battery across the unknown resistor (with an internal resistor of a known value in series) producing a current which drives a meter movement. The current, in accordance with Ohm's law, is inversely proportional to the sum of the internal resistance and the resistor being tested, resulting in an analog meter scale which is very non-linear, calibrated from infinity to 0 ohms. A digital multimeter, using active electronics, may instead pass a specified current through the test resistance. The voltage generated across the test resistance in that case is linearly proportional to its resistance, which is measured and displayed. In either case the low-resistance ranges of the meter pass much more current through the test leads than do high-resistance ranges, in order for the voltages present to be at reasonable levels (generally below 10 volts) but still measurable.Measuring low-value resistors, such as fractional-ohm resistors, with acceptable accuracy requires four-terminal connections. One pair of terminals applies a known, calibrated current to the resistor, while the other pair senses the voltage drop across the resistor. Some laboratory quality ohmmeters, especially milliohmmeters, and even some of the better digital multimeters sense using four input terminals for this purpose, which may be used with special test leads. Each of the two so-called Kelvin clips has a pair of jaws insulated from each other. One side of each clip applies the measuring current, while the other connections are only to sense the voltage drop. The resistance is again calculated using Ohm's Law as the measured voltage divided by the applied current.

Standards

Production resistors

Resistor characteristics are quantified and reported using various national standards. In the US, MIL-STD-202[17] contains the relevant test methods to which other standards refer.There are various standards specifying properties of resistors for use in equipment:

- BS 1852

- EIA-RS-279

- MIL-PRF-26

- MIL-PRF-39007 (Fixed Power, established reliability)

- MIL-PRF-55342 (Surface-mount thick and thin film)

- MIL-PRF-914

- MIL-R-11 STANDARD CANCELED

- MIL-R-39017 (Fixed, General Purpose, Established Reliability)

- MIL-PRF-32159 (zero ohm jumpers)

- UL 1412 (fusing and temperature limited resistors) [18]

Resistance standards

The primary standard for resistance, the "mercury ohm" was initially defined in 1884 in as a column of mercury 106.3 cm long and 1 square millimeter in cross-section, at 0 degrees Celsius. Difficulties in precisely measuring the physical constants to replicate this standard result in variations of as much as 30 ppm. From 1900 the mercury ohm was replaced with a precision machined plate of manganin.[19] Since 1990 the international resistance standard has been based on the quantized Hall effect discovered by Klaus von Klitzing, for which he won the Nobel Prize in Physics in 1985.[20]Resistors of extremely high precision are manufactured for calibration and laboratory use. They may have four terminals, using one pair to carry an operating current and the other pair to measure the voltage drop; this eliminates errors caused by voltage drops across the lead resistances, because no charge flows through voltage sensing leads. It is important in small value resistors (100–0.0001 ohm) where lead resistance is significant or even comparable with respect to resistance standard value.[21]

Resistor marking

Main article: Electronic color code

Most axial resistors use a pattern of colored stripes to indicate

resistance, which also indicate tolerance, and may also be extended to

show temperature coefficient and reliability class. Cases are usually

tan, brown, blue, or green, though other colors are occasionally found

such as dark red or dark gray. The power rating is not usually marked

and is deduced from the size.The color bands of the carbon resistors can be three, four, five or, six bands. The first two bands represent first two digits to measure their value in ohms. The third band of a three- or four-banded resistor represents multiplier; a fourth band denotes tolerance (which if absent, denotes ±20%). For five and six color-banded resistors, the third band is a third digit, fourth band multiplier and fifth is tolerance. The sixth band represents temperature co-efficient in a six-banded resistor.

Surface-mount resistors are marked numerically, if they are big enough to permit marking; more-recent small sizes are impractical to mark.

Early 20th century resistors, essentially uninsulated, were dipped in paint to cover their entire body for color-coding. A second color of paint was applied to one end of the element, and a color dot (or band) in the middle provided the third digit. The rule was "body, tip, dot", providing two significant digits for value and the decimal multiplier, in that sequence. Default tolerance was ±20%. Closer-tolerance resistors had silver (±10%) or gold-colored (±5%) paint on the other end.

Preferred values

See also: Preferred number § E series

Early resistors were made in more or less arbitrary round numbers; a

series might have 100, 125, 150, 200, 300, etc. Resistors as

manufactured are subject to a certain percentage tolerance,

and it makes sense to manufacture values that correlate with the

tolerance, so that the actual value of a resistor overlaps slightly with

its neighbors. Wider spacing leaves gaps; narrower spacing increases

manufacturing and inventory costs to provide resistors that are more or

less interchangeable.A logical scheme is to produce resistors in a range of values which increase in a geometric progression, so that each value is greater than its predecessor by a fixed multiplier or percentage, chosen to match the tolerance of the range. For example, for a tolerance of ±20% it makes sense to have each resistor about 1.5 times its predecessor, covering a decade in 6 values. In practice the factor used is 1.4678, giving values of 1.47, 2.15, 3.16, 4.64, 6.81, 10 for the 1–10-decade (a decade is a range increasing by a factor of 10; 0.1–1 and 10–100 are other examples); these are rounded in practice to 1.5, 2.2, 3.3, 4.7, 6.8, 10; followed, by 15, 22, 33, … and preceded by … 0.47, 0.68, 1. This scheme has been adopted as the E6 series of the IEC 60063 preferred number values. There are also E12, E24, E48, E96 and E192 series for components of progressively finer resolution, with 12, 24, 96, and 192 different values within each decade. The actual values used are in the IEC 60063 lists of preferred numbers.

A resistor of 100 ohms ±20% would be expected to have a value between 80 and 120 ohms; its E6 neighbors are 68 (54–82) and 150 (120–180) ohms. A sensible spacing, E6 is used for ±20% components; E12 for ±10%; E24 for ±5%; E48 for ±2%, E96 for ±1%; E192 for ±0.5% or better. Resistors are manufactured in values from a few milliohms to about a gigaohm in IEC60063 ranges appropriate for their tolerance. Manufacturers may sort resistors into tolerance-classes based on measurement. Accordingly a selection of 100 ohms resistors with a tolerance of ±10%, might not lie just around 100 ohm (but no more than 10% off) as one would expect (a bell-curve), but rather be in two groups – either between 5 to 10% too high or 5 to 10% too low (but not closer to 100 ohm than that) because any resistors the factory had measured as being less than 5% off would have been marked and sold as resistors with only ±5% tolerance or better. When designing a circuit, this may become a consideration.

Earlier power wirewound resistors, such as brown vitreous-enameled types, however, were made with a different system of preferred values, such as some of those mentioned in the first sentence of this section.

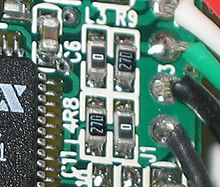

SMT resistors

This image shows four surface-mount resistors (the component at the upper left is a capacitor) including two zero-ohm resistors.

Zero-ohm links are often used instead of wire links, so that they can

be inserted by a resistor-inserting machine. Their resistance is

non-zero but negligible.

| 334 | = 33 × 104 ohms = 330 kilohms |

| 222 | = 22 × 102 ohms = 2.2 kilohms |

| 473 | = 47 × 103 ohms = 47 kilohms |

| 105 | = 10 × 105 ohms = 1 megohm |

| 100 | = 10 × 100 ohm = 10 ohms |

| 220 | = 22 × 100 ohm = 22 ohms |

Resistances less than 10 ohms have 'R' to indicate the position of the decimal point (radix point). For example:

| 4R7 | = 4.7 ohms |

| R300 | = 0.30 ohms |

| 0R22 | = 0.22 ohms |

| 0R01 | = 0.01 ohms |

| 1001 | = 100 × 101 ohms = 1.00 kilohm |

| 4992 | = 499 × 102 ohms = 49.9 kilohm |

| 1000 | = 100 × 100 ohm = 100 ohms |

More recent surface-mount resistors are too small, physically, to permit practical markings to be applied.

Industrial type designation

| Type No. | Power rating (watts) |

MIL-R-11 Style |

MIL-R-39008 Style |

|---|---|---|---|

| BB | 1⁄8 | RC05 | RCR05 |

| CB | 1⁄4 | RC07 | RCR07 |

| EB | 1⁄2 | RC20 | RCR20 |

| GB | 1 | RC32 | RCR32 |

| HB | 2 | RC42 | RCR42 |

| GM | 3 | - | - |

| HM | 4 | - | - |

| Industrial type designation | Tolerance | MIL Designation |

|---|---|---|

| 5 | ±5% | J |

| 2 | ±20% | M |

| 1 | ±10% | K |

| - | ±2% | G |

| - | ±1% | F |

| - | ±0.5% | D |

| - | ±0.25% | C |

| - | ±0.1% | B |

Electrical and thermal noise

In amplifying faint signals, it is often necessary to minimize electronic noise, particularly in the first stage of amplification. As a dissipative element, even an ideal resistor will naturally produce a randomly fluctuating voltage or "noise" across its terminals. This Johnson–Nyquist noise is a fundamental noise source which depends only upon the temperature and resistance of the resistor, and is predicted by the fluctuation–dissipation theorem. Using a larger value of resistance produces a larger voltage noise, whereas with a smaller value of resistance there will be more current noise, at a given temperature.The thermal noise of a practical resistor may also be larger than the theoretical prediction and that increase is typically frequency-dependent. Excess noise of a practical resistor is observed only when current flows through it. This is specified in unit of μV/V/decade – μV of noise per volt applied across the resistor per decade of frequency. The μV/V/decade value is frequently given in dB so that a resistor with a noise index of 0 dB will exhibit 1 μV (rms) of excess noise for each volt across the resistor in each frequency decade. Excess noise is thus an example of 1/f noise. Thick-film and carbon composition resistors generate more excess noise than other types at low frequencies. Wire-wound and thin-film resistors are often used for their better noise characteristics. Carbon composition resistors can exhibit a noise index of 0 dB while bulk metal foil resistors may have a noise index of −40 dB, usually making the excess noise of metal foil resistors insignificant.[23] Thin film surface mount resistors typically have lower noise and better thermal stability than thick film surface mount resistors. Excess noise is also size-dependent: in general excess noise is reduced as the physical size of a resistor is increased (or multiple resistors are used in parallel), as the independently fluctuating resistances of smaller components will tend to average out.

While not an example of "noise" per se, a resistor may act as a thermocouple, producing a small DC voltage differential across it due to the thermoelectric effect if its ends are at different temperatures. This induced DC voltage can degrade the precision of instrumentation amplifiers in particular. Such voltages appear in the junctions of the resistor leads with the circuit board and with the resistor body. Common metal film resistors show such an effect at a magnitude of about 20 µV/°C. Some carbon composition resistors can exhibit thermoelectric offsets as high as 400 µV/°C, whereas specially constructed resistors can reduce this number to 0.05 µV/°C. In applications where the thermoelectric effect may become important, care has to be taken to mount the resistors horizontally to avoid temperature gradients and to mind the air flow over the board.[24]

Failure modes

The failure rate of resistors in a properly designed circuit is low compared to other electronic components such as semiconductors and electrolytic capacitors. Damage to resistors most often occurs due to overheating when the average power delivered to it (as computed above) greatly exceeds its ability to dissipate heat (specified by the resistor's power rating). This may be due to a fault external to the circuit, but is frequently caused by the failure of another component (such as a transistor that shorts out) in the circuit connected to the resistor. Operating a resistor too close to its power rating can limit the resistor's lifespan or cause a significant change in its resistance. A safe design generally uses overrated resistors in power applications to avoid this danger.Low-power thin-film resistors can be damaged by long-term high-voltage stress, even below maximum specified voltage and below maximum power rating. This is often the case for the startup resistors feeding the SMPS integrated circuit.[citation needed]

When overheated, carbon-film resistors may decrease or increase in resistance.[25] Carbon film and composition resistors can fail (open circuit) if running close to their maximum dissipation. This is also possible but less likely with metal film and wirewound resistors.

There can also be failure of resistors due to mechanical stress and adverse environmental factors including humidity. If not enclosed, wirewound resistors can corrode.

Surface mount resistors have been known to fail due to the ingress of sulfur into the internal makeup of the resistor. This sulfur chemically reacts with the silver layer to produce non-conductive silver sulfide. The resistor's impedance goes to infinity. Sulfur resistant and anti-corrosive resistors are sold into automotive, industrial, and military applications. ASTM B809 is an industry standard that tests a part's susceptibility to sulfur.

An alternative failure mode can be encountered where large value resistors are used (hundreds of kilohms and higher). Resistors are not only specified with a maximum power dissipation, but also for a maximum voltage drop. Exceeding this voltage will cause the resistor to degrade slowly reducing in resistance. The voltage dropped across large value resistors can be exceeded before the power dissipation reaches its limiting value. Since the maximum voltage specified for commonly encountered resistors is a few hundred volts, this is a problem only in applications where these voltages are encountered.

Variable resistors can also degrade in a different manner, typically involving poor contact between the wiper and the body of the resistance. This may be due to dirt or corrosion and is typically perceived as "crackling" as the contact resistance fluctuates; this is especially noticed as the device is adjusted. This is similar to crackling caused by poor contact in switches, and like switches, potentiometers are to some extent self-cleaning: running the wiper across the resistance may improve the contact. Potentiometers which are seldom adjusted, especially in dirty or harsh environments, are most likely to develop this problem. When self-cleaning of the contact is insufficient, improvement can usually be obtained through the use of contact cleaner (also known as "tuner cleaner") spray. The crackling noise associated with turning the shaft of a dirty potentiometer in an audio circuit (such as the volume control) is greatly accentuated when an undesired DC voltage is present, often indicating the failure of a DC blocking capacitor in the circuit.

No comments:

Post a Comment